What kind of steel is used for the injection molding molds of PE?

Polyethylene (PE) is one of the most widely used general-purpose thermoplastics, including LDPE, HDPE, and LLDPE. It features low viscosity, non-corrosiveness, and excellent melt flow, with a stable injection molding temperature range of 160℃~220℃. Mold steel selection for PE does not require a focus on corrosion resistance; instead, it centers on production volume, product precision, surface finish requirements, and PE material characteristics, while balancing processing efficiency and cost control.

1. Standard Production Volume: Pre-hardened Steel

For small to medium production runs (100,000 to 500,000 cycles) or standard PE products with low surface finish requirements, pre-hardened steel is the most cost-effective choice. These steels are delivered with stable hardness, eliminating the need for post-fabrication heat treatment and enabling direct machining, which shortens mold lead times and reduces deformation risks.

P20 (Domestic grade: 3Cr2Mo): A versatile general-purpose mold steel with a hardness of 28~35HRC, offering good machinability and dimensional stability. It is ideal for standard HDPE crates and LDPE daily necessities, providing a balance of performance and cost.

718H (Domestic grade: P20Ni): An improved version of P20 with higher purity and uniform hardness (32~38HRC). It delivers better polishability and fatigue resistance, making it suitable for medium production runs (500,000 to 1,000,000 cycles) or products with moderate surface finish requirements.

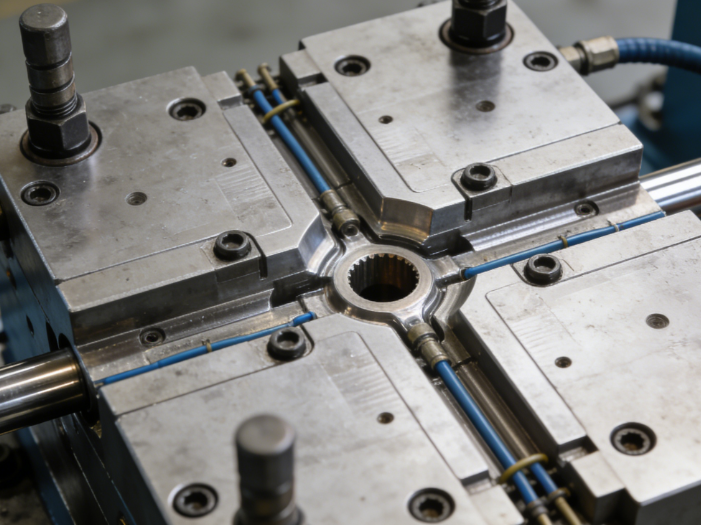

2. High Production Volume & Precision: Hardened and Tempered Steel

For high-volume production (over 1,000,000 cycles) or precision PE products such as pipes, automotive components, and high-pressure fittings, pre-hardened steel lacks sufficient wear resistance. Hardened and tempered steel, which achieves 45~55HRC after heat treatment, offers superior wear resistance, compressive strength, and dimensional stability.

H13 (Domestic grade: 4Cr5MoSiV1): A hot work steel with excellent thermal fatigue resistance and wear resistance. After quenching and tempering, it reaches 48~52HRC, effectively resisting melt erosion in high-pressure HDPE pipe molding. Surface nitriding can further increase surface hardness to over 65HRC, extending mold life for millions of cycles.

SKD61: A premium hot work steel with higher molybdenum content and a more uniform microstructure, providing better toughness and thermal crack resistance than H13. It is ideal for high-precision PE molds requiring extreme durability, such as automotive components.

3. High Surface Finish & Special Applications

For PE products requiring high gloss, fine textures, or corrosion resistance, specialized mirror-polish or stainless steels are required.

S136 (Domestic grade: 4Cr13): A martensitic stainless steel with exceptional mirror polishability (SPI A1 grade) and corrosion resistance. It is used for cosmetic packaging and high-gloss daily necessities, where surface quality is critical.

NAK80: An age-hardening steel with pre-hardened hardness of ~40HRC and near-mirror polishability. It offers higher machining efficiency than S136, making it suitable for high-gloss PE containers and precision electronic parts.

4. Material-Specific Considerations

HDPE: Higher viscosity and injection pressure demand better wear resistance, so 718H or H13 is recommended.

LDPE: Excellent flow increases flash risk, requiring steels with high dimensional stability like 718H or S136, paired with strict mold gap control.

LLDPE: High tensile strength increases ejection friction, necessitating polished or coated mold surfaces (e.g., DLC coating) to prevent scratching.

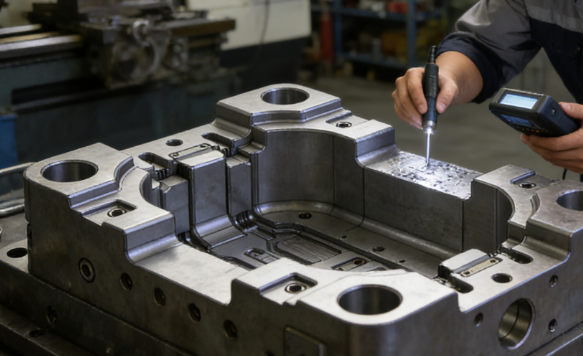

5. Selection Guidelines

Production Volume: Small/medium runs → P20/718H; high-volume runs → H13/SKD61.

Surface Finish: Standard → P20; high-gloss/textured → 718H/NAK80; optical grade → S136.

Cost Optimization: Use cost-effective domestic grades (e.g., 3Cr2Mo instead of imported P20) where performance allows.

Surface Treatment: For high-volume molds, nitriding or PVD coating is highly recommended to extend mold life.

By following these guidelines, you can ensure optimal mold performance, reduce costs, and enhance production efficiency for PE injection molding.