Emergency Solutions for Stuck Ejector Pins in Plastic Molds

Stuck ejector pins are a frequent sudden fault in plastic injection molding, mainly caused by plastic residue jamming, lubrication failure, slight ejector pin deformation, metal shavings in fitting gaps or thermal expansion of ejector pins due to high mold temperature. Forcing ejection or prying will cause secondary damage like broken ejector pins, cavity scratches and ejector plate deformation. The emergency treatment follows the principles of safety lock first, inspection before operation, gentle handling instead of forced action, with all on-site operations completed without mold disassembly to resume production quickly and protect mold precision. The specific practices and taboos are as follows:

Ⅰ. Pre-operation Safety Measures

Stop the machine immediately, turn off the automatic ejection and mold opening/closing functions of the injection molding machine, and cut off the electric control signal of mold-related actions to prevent equipment misoperation from worsening the fault.

Set the injection molding machine to manual jog mode, and keep the mold clamping mechanism in low-pressure mold release state to avoid extruding the ejector pin assembly during mold closing.

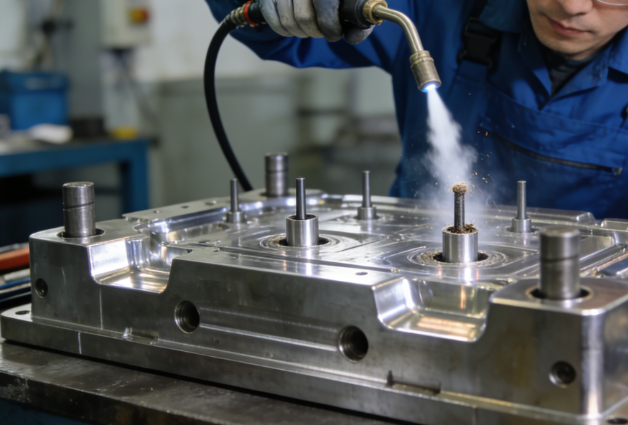

Clean plastic residues on the mold parting surface and around ejector pin holes to prevent foreign matter from falling into fitting gaps. Prepare special tools such as copper shovels, copper rods, mold-specific high-pressure air guns and high-temperature wear-resistant lubricating grease. Do not use hard metal tools such as screwdrivers and iron crowbars on the mold cavity and ejector pin fitting surfaces.

Ⅱ. Rapid Fault Cause Inspection

Quickly locate the cause of the stuck pins through visual inspection and gentle manual touch without on-site mold disassembly, focusing on 4 common problems:

Foreign matter jamming: The most common cause, with plastic residue, shavings, iron filings or dust agglomerated in the fitting gap between ejector pin holes and pins, visible to the naked eye.

Lubrication failure: No lubricating grease on the fitting surfaces of ejector pins, guide sleeves and pin holes, causing dry friction jamming with dry wear marks on contact surfaces.

Slight deformation/bending of ejector pins: Uneven ejection force leads to slight pin deformation, with an obvious fixed stuck point when pushing the ejector plate gently by hand.

Thermal expansion jamming: Continuous high-temperature production causes thermal expansion of ejector pins and reduced fitting gaps, mostly occurring in high mold temperature production of thick-walled parts, and the jamming eases slightly after a short machine stop for cooling.

Ⅲ. Targeted On-site Emergency Unlocking

Aim at the identified causes, unlock the pins step by step with gentle handling, and follow the order of first cleaning foreign matter, then lubricating, finally correcting without forced action:

1. Foreign matter jamming

Adjust a mold-specific high-pressure air gun to medium pressure, and blow repeatedly along the fitting surface of ejector plate and cavity, around ejector pin holes and the fitting part of ejector pin return rods to blow out foreign matter such as shavings and iron filings. Gently scrape off agglomerated plastic residue with a copper shovel; do not dig or pry hard to prevent damaging the precision fitting surfaces of pins and holes. Wipe the exposed section of ejector pins with a clean lint-free cloth after blowing to ensure no residual foreign matter.

2. Lubrication failure

Evenly apply mold-specific high-temperature wear-resistant lubricating grease (suitable for 150-200℃ working temperature of injection molds, ordinary butter is forbidden) on the exposed fitting section of stuck ejector pins and the guide sleeves of ejector plates. Twist the exposed end of ejector pins gently with fingers to let the grease seep into the fitting gaps. Then push the ejector plate by hand or activate the machine's low-pressure slow ejection function (set ejection force below 30% of the rated value) to move the pins slowly until the jamming is released.

3. Slight deformation/bending of ejector pins

If a single pin is confirmed to be stuck due to slight deformation, gently press a copper rod against the tail (non-cavity end) of the deformed pin and tap slowly along the ejection direction, with the force limited to minor correction; do not hit hard to avoid pin breakage. After correction, blow clean with a high-pressure air gun, apply lubricating grease, and test the pin movement by manual jog. If the stuck point still exists, appropriately reduce the ejection speed to maintain production first, and replace the deformed pin during production breaks.

4. Thermal expansion jamming

Turn off the mold heating system immediately, suspend production and let the mold cool naturally for 10-15 minutes (no forced water cooling to prevent mold cracking due to excessive temperature difference). After the ejector pins shrink naturally, apply high-temperature lubricating grease, then move the ejector plate by manual jog. Resume production after smooth movement, and appropriately lower the mold working temperature subsequently to avoid re-jamming caused by thermal expansion.

Ⅳ. Post-unlocking Test Run Verification

After the jamming is released, set the ejection force of the injection molding machine to 50% of the rated pressure, adopt manual slow ejection and retraction mode, and repeat the operation 3-5 times to check whether all ejector pins eject and reset smoothly without stuck points or deflection.

Jog the mold opening and closing 2-3 times to check whether the ejector pins reset in place, the parting surface fits tightly, and there is no mold closing interference caused by exposed ejector pins.

Conduct 1-2 trial injections to check that the plastic parts have no white marks, cracks or short shots caused by ejection, with uniform ejection traces. Restore normal production parameters after confirming no mold abnormalities.

Ⅴ. Absolute On-site Operation Taboos

Do not activate high-pressure ejection when the pins are stuck to avoid broken ejector pins, deformed ejector plates or cracked mold cavities.

Do not pry the ejector plate or dig the ejector pin holes with hard metal tools such as iron crowbars and screwdrivers to prevent scratching the precision fitting surfaces and aggravating subsequent jamming.

Do not apply low-temperature lubricants such as machine oil and ordinary butter on the ejector pin fitting surfaces; such lubricants are easy to carbonize at high temperature, forming carbon deposits and causing re-jamming.

Do not force the ejection of a single ejector pin to prevent uneven stress and deflection of the ejector plate, leading to simultaneous jamming of multiple pins.

Ⅵ. Simple Recurrence Prevention Inspection During Production Breaks

After resuming production through emergency treatment, conduct 3 quick inspections during production breaks such as mold and material change to avoid re-jamming:

Visually inspect all ejector pins for deformation, wear and bending, and check ejector pin holes for plastic residue and carbon deposits; replace defective parts in a timely manner.

Reapply high-temperature lubricating grease to all ejector pin fitting surfaces and ejector plate guide sleeves with full coverage and no dead angles.

Check the flexibility of ejector pin return rods and the effectiveness of return springs to ensure accurate reset of ejector pins after each ejection without jamming risks.