-

How to Judge the Compatibility of Two-Color Injection Molding Materials

Two-color injection molding technology is widely used in automotive, electronic, home appliance fields for integrated functions and diversified appearances. Material compatibility directly determines

2025/12/24 Two-Color Injection Molding

-

Key Considerations for Two-Color Overmolding Injection Molding

Two-color overmolding combines substrate and overmold layers to achieve both functionality and comfort in products like tool handles, automotive seals, and electronic sheaths. Its core value lies in t

2025/12/23 Two-Color Overmolding

-

TPU Elastic Product Molding Process

Thermoplastic Polyurethane (TPU) integrates the high elasticity of rubber and the processability of plastic, and is widely applied in shoe materials, automotive shock absorbers, electronic protective

2025/12/23 TPU

-

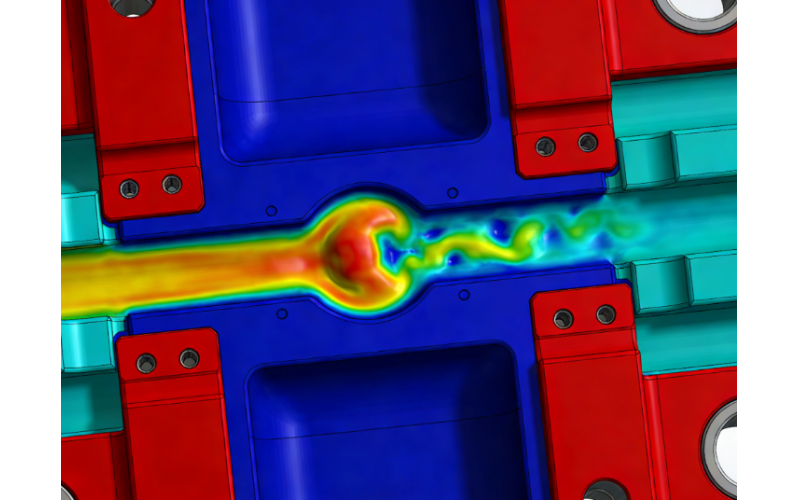

Concise Optimization Strategies for Injection Mold Exhaust Systems

The exhaust system of injection molds is critical for smooth melt filling and defect elimination, directly impacting product quality and production efficiency. Poor design causes bubbles, charring, sh

2025/12/22 Injection Mold

-

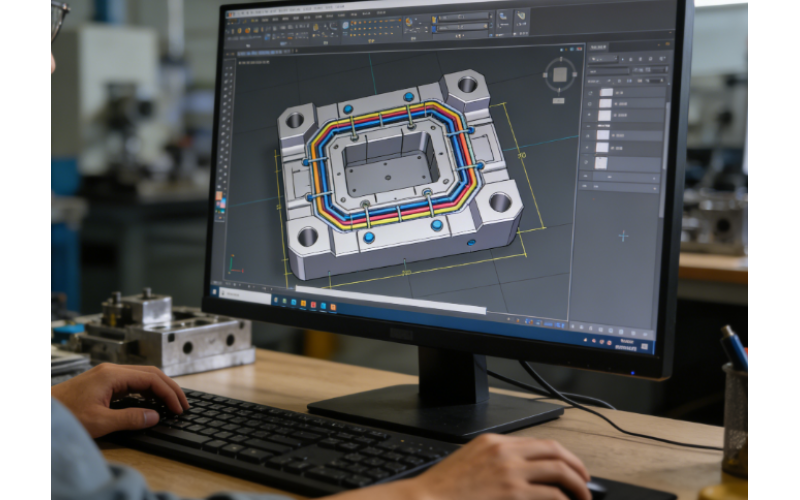

Core Technical Points of Injection Mold Design

Injection mold design integrates product structure analysis, material adaptation, process optimization, precision control and production economy, directly determining plastic product quality, efficien

2025/12/22 Injection Mold

-

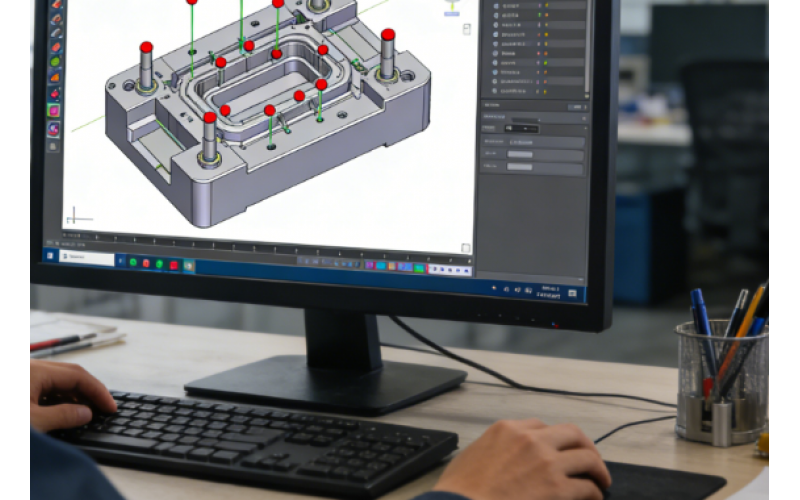

Key Design Points of Injection Mold Ejection Mechanisms

The ejection mechanism of an injection mold is a core component of injection molding, directly determining the smoothness of product demolding, surface integrity and production efficiency. Rational de

2025/12/20 Injection Mold

-

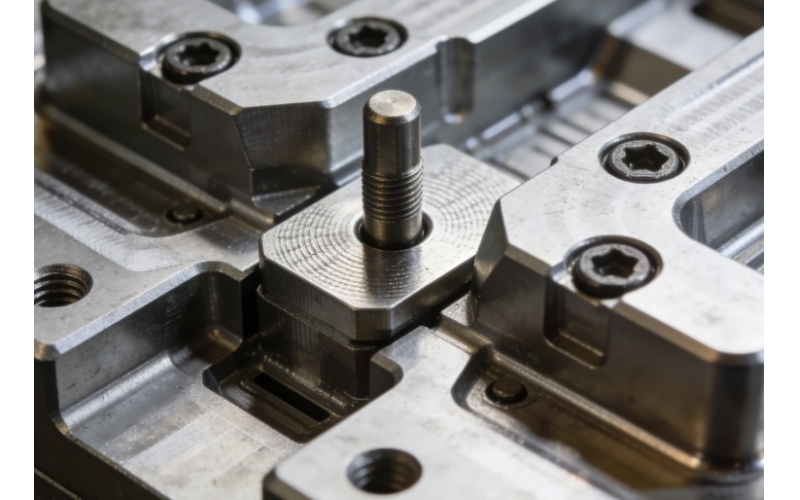

Process Standards for Surface Treatment of Injection Molds

Surface treatment of injection molds is a key link in mold manufacturing, directly affecting product surface quality, mold service life and production efficiency. Scientific and standardized process s

2025/12/20 Injection Molds

-

How to Solve Product Shedding Problems in Insert Molding

In insert molding, product shedding is a frequent and intractable issue, reducing production efficiency, increasing scrap rates and raising costs, which harms enterprise economic benefits. Insert mold

2025/12/19 Insert injection mold